When it comes to multi-level bill of materials, it is difficult to analyze unit costs accurately. This model example is designed to assist vertically integrated manufacturing organizations to monitor finished good costs and analyze pricing based on the company's bill of materials

This model example is showcase the art of the possible. Our configurable Application found here

Features

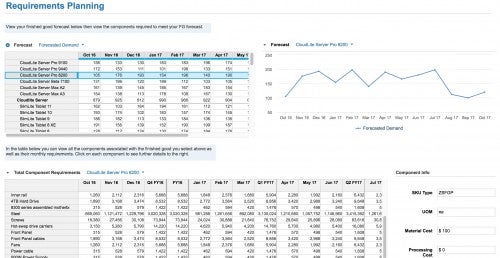

Component Requirements Planning

- View how many components are needed to meet the finish good demand over time.

- These components can be at any level of the BOM structure, any number of times for different finished goods.

- Filter component requirements by item type: Raw Materials, Semi-Finished Purchased Goods, and Packaging Materials.

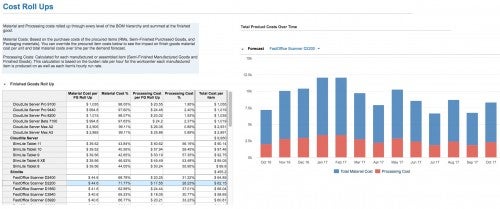

Material Cost BOM Roll Up

- Roll up material costs from every level of the BOM to each finished good.

- Override any procured material purchase costs to see impact on all related finished goods costs.

Processing Cost BOM Roll Up

- For manufactured or assembled items (Semi-Finished Manufactured and Finished Goods), see the processing costs roll up through every BOM level.

- These processing costs are based on hourly work-center burden rate and item run rates.

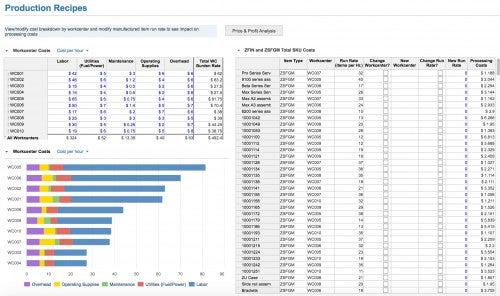

Set Production Recipes

- Analyze a breakdown of each work center's costs.

- Assign work centers to processed SKUs.

- See impact on all finished good costs based on changes to work center costs.

Analyze Finished Good Margin

- Review material and processing costs for each finished good and current sale price.

- Set profit margin percentage targets at brand level and review finished goods under target.

- Override current selling price to see impact on revenue and margin over time.

Information

Size

41 MB

Language

English

Stats

Modules

39

Roles

2

Formulas

247

Reports

8

Complexity

Intermediate

termsTitle